Install in minutes, not days

Each unit arrives almost fully assembled, dramatically reducing site time and contractor variability compared to the time required of traditional concrete.

Rapid-install EV charger foundations engineered for consistency, safety and future-ready upgrades. SwiftBase is Formula Space’s next-generation foundation system - pre-assembled, D400-rated and designed specifically for the EV sector, eliminating the guesswork, delays and inaccuracies of traditional civils.

Foundations built for the future of EV charging.

Each unit arrives nearly complete, installs in minutes, and delivers a consistent, D400-rated base ready for today’s chargers and tomorrow’s upgrades.

With generous access for cabling, built-in retention sockets, and designs matched to the UK’s leading CPOs and OEMs, SwiftBase gives operators a faster, cleaner and more controlled way to deliver EV infrastructure at scale.

D400-rated stability

Superior cable access & maintenance

OEM-matched designs

Stock-ready with rapid lead times

Each unit arrives almost fully assembled, dramatically reducing site time and contractor variability compared to the time required of traditional concrete.

This isn’t a repurposed civils block. It’s a system built by EV specialists:

Upgrades shouldn’t require digging your site up.

SwiftBase enables:

Quick swap-out of bollards via retention sockets

Easy charger replacement

Expansion without re-pouring foundations

Consistent results, whatever the site demands.

SwiftBase arrives in pre-assembled sections engineered for consistency across every site. The modular format eliminates on-site variability, reduces installation errors and delivers a repeatable foundation platform for scale deployment.

SwiftBase installs in hours, not days. No shuttering, rebar or weather delays. A predictable, repeatable process that accelerates every programme.

Heavy-duty construction ensures long-term stability under vehicle and charger loads. The intelligent retention design prevents charger movement and removes wobble issues seen in conventional pads.

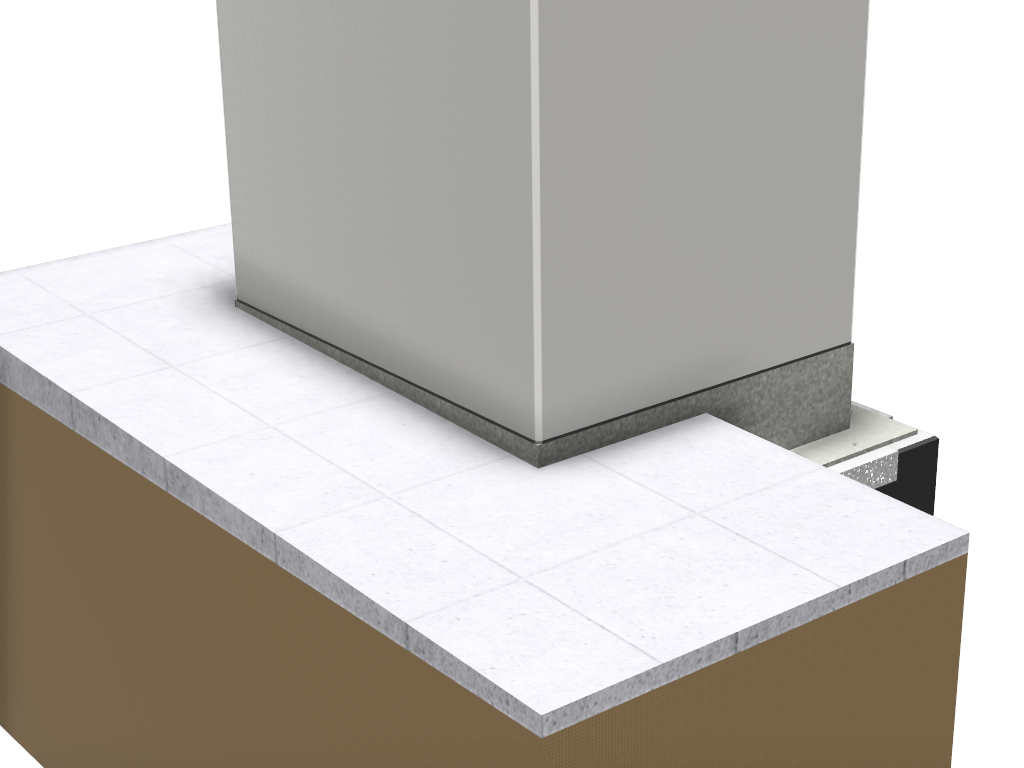

With up to 85% of the charger footprint available for access, SwiftBase enables faster cable pull-through, easier terminations and straightforward future upgrades - all without destructive civils work.

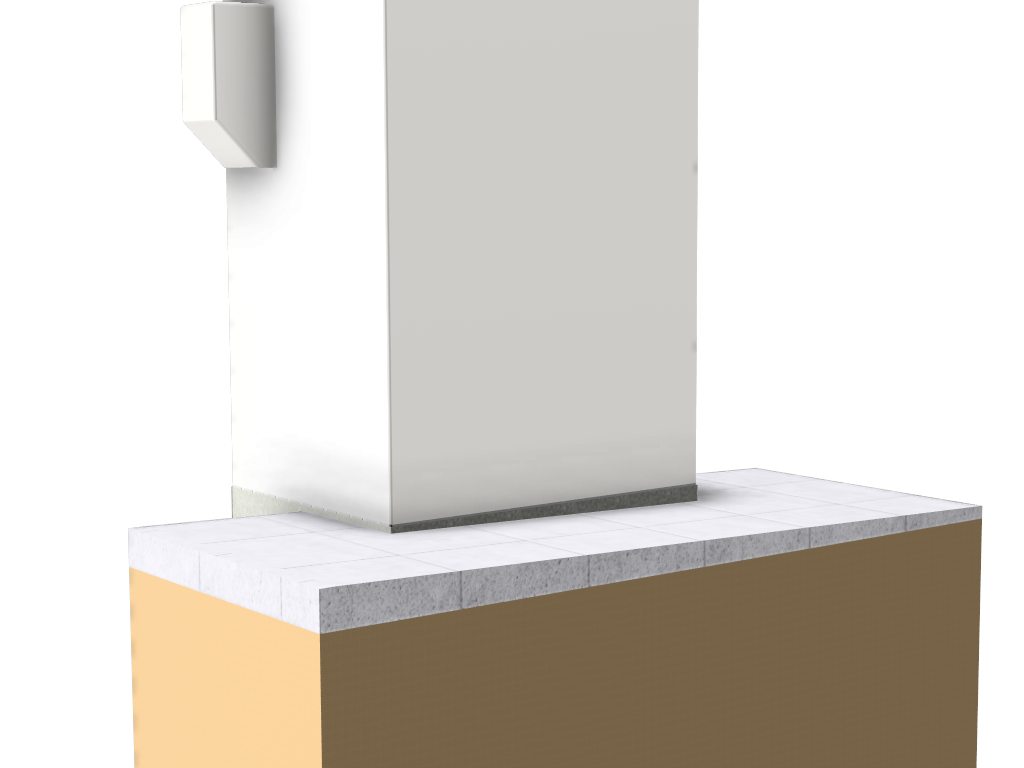

Engineered to adapt to uneven or difficult ground conditions, SwiftBase maintains surface-level accuracy and accessibility while avoiding the trip hazards and unsightly workarounds common with generic plinths.

Unlike cast concrete pads, SwiftBase supports low-cost hardware upgrades with minimal disruption. Chargers can be removed and replaced without breaking ground, reducing downtime and protecting long-term asset value.

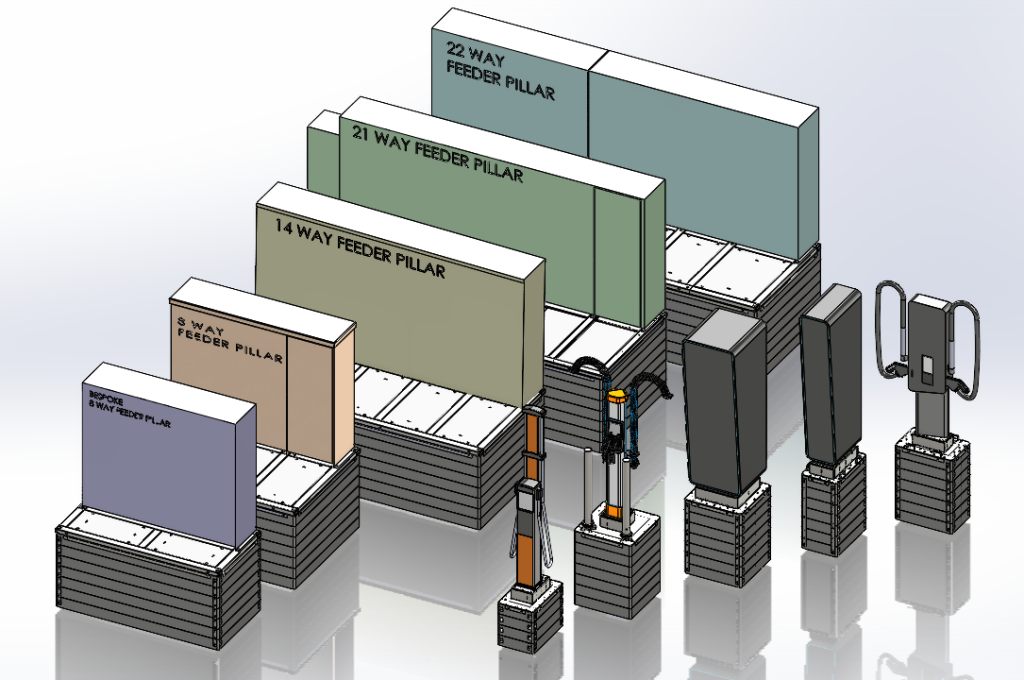

One foundation system for every major asset.

SwiftBase isn’t only built for chargers, the product provides a unified, high-access foundation solution.

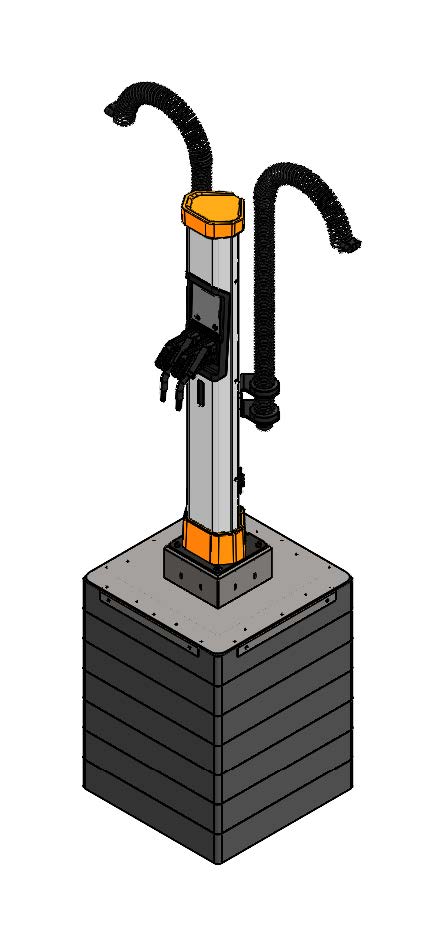

Feeder pillars demand stability, space and reliable access, and SwiftBase delivers all three. Each unit is engineered with generous cable management apertures and removable top panels that expose up to 85% of the foundation footprint, giving engineers unparalleled access for installation, inspections, upgrades and thermal checks.

Instead of working through a small concrete hatch, maintenance teams can simply lift the panel and reach everything they need without excavation or disruption. The result is a safer, cleaner and more consistent way to install and service the most critical electrical asset on site.

Wide removable access plates allow engineers to work inside the foundation safely and efficiently. Ideal for cable routing, switchgear changes or future electrical upgrades.

SwiftBase includes dedicated feeder pillar variants matched to common OEM cabinet sizes, providing a D400-rated, pre-assembled base built for heavy, high-capacity equipment

Using SwiftBase for both chargers and feeder pillars ensures a uniform installation approach, reducing contractor variability, speeding up deployment and delivering a cleaner finished result.

Gradient Friendly

No Trip Hazards

Zero Wobble

Accessibility Maintained

Compliance Without Compromise

Hassle-Free Install

Gradient Friendly

No Trip Hazards

Zero Wobble

Accessibility Maintained

Compliance Without Compromise

Hassle-Free Install

A fast, repeatable installation designed for modern EV rollouts.

SwiftBase arrives assembled and ready to drop into place, removing the delays and variability of traditional concrete pours. Every step of the process has been designed to minimise disruption, reduce installation time and give charge point operators complete programme certainty.

30 – 60 Mins

10

Mins

10-20

Mins

10

Mins

45 – 90

Mins

TOTAL

1:45 – 3:10

Hours

Traditional Methods

Features | SwiftBase | Concrete |

|---|---|---|

| Advanced analytics | ||

| Structurally robust platform - D400 rated | ||

| Custom branding | ||

| Installation time | 1:40 – 3:00 Hours | 2:00 – 3:15 Hours |

| Storage integrations | ||

| Curing time | 24 – 48 Hours* | |

| AI assistant | ||

| Arrives pre-constructed | ||

| Automated reports | ||

| Futureproof for hardware upgrades | ||

| Cable access up to 85% of footprint | ||

| Compatible with site gradients | ||

| Warehouse stock for next-day dispatch | ||

| Shuttering, rebar & on-site assembly required | ||

| Weather dependant installation | ||

“Formula Space’s foundation systems are becoming an integral part of our site design. The product saves us construction time and ensures a clean, consistent and reliable installation that future-proofs our sites for charger upgrades down the road.

Just as importantly, the Formula Space team have been excellent to work with, they are proactive, responsive and committed to keeping our projects on track.”